A new material developed at UNSW that can store digital information and be printed onto various surfaces, could be used for memory cells in next-generation, large-scale printable electronics.

The material, made from the rare earth mineral cerium oxide, is comprised of tiny cubes that are roughly 10 nanometres thick, or about 10,000 times smaller than the thickness of a sheet of paper.

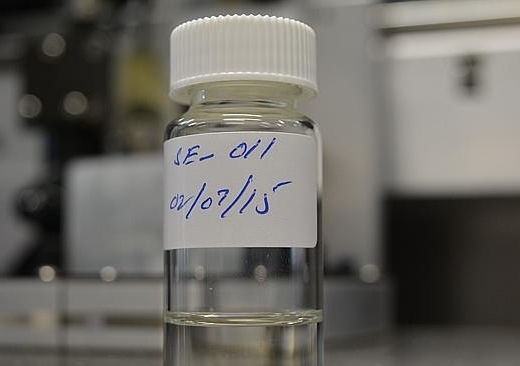

When placed in a solution and deposited onto a conductive surface via ink-jet printer, the cubes self-assemble: first they form a coordinated square array, then they stack on top of each other like Lego, building up layer by layer.

This is a next-generation memory technology that requires less voltage, consumes less power and can write/erase information faster than conventional memory devices.

Conceptually, more than two trillion cubes could fit in a memory cell configuration the size of a standard postage stamp, says Professor Sean Li from the UNSW School of Materials Science and Engineering.

Digital information (a series of ones and zeroes) is encoded and stored on the nanocube memory cells by applying an electrical current, which changes the cell between a resistive and conductive state.

Professor Li, who led the team developing the new material with UNSW colleagues Dr Adnan Younis and Dr Dewei Chu, says the nanocubes have unique physical properties for microelectronics, and could be used for resistive random access memory (RRAM) devices.

“Rapid innovations in printing technology over the last few years mean this material could hold enormous potential for a range of future industries."

Professor Sean Li and Dr Adnan Younis from UNSW's School of Materials Science and Engineering

This is a next-generation memory technology that requires less voltage, consumes less power and can write/erase information faster than conventional memory devices, such as flash drives and conventional hard disk, says Professor Li.

“Rapid innovations in printing technology over the last few years mean this material could hold enormous potential for a range of future industries,” says Professor Li.

Memory cells made from these nanocubes could have applications in wearable electronics, mobile devices and computers, and a range of other connected devices and products that will come online with the continued expansion of the Internet of Things.

“From our perspective, we had a technology with a global market that is unlike anything else available, developed by a team of passionate researchers at the number one materials science school in the country.”

The researchers have demonstrated that the nanocube ink can be jetted from a commercial ink-jet printer onto both silicon and glass surfaces. And importantly, the ink is transparent, which means it can be used directly on screens and displays.

The technology has been freely licensed to Australian company Strategic Elements through an Easy Access IP deal with the University’s commercialisation unit, UNSW Innovations.

Charles Murphy, Managing Director of Strategic Elements, says the company was looking for technologies that leverage the properties of rare earth materials and was impressed by the cerium oxide nanocubes.

“From our perspective, we had a technology with a global market that is unlike anything else available, developed by a team of passionate researchers at the number one materials science school in the country,” he says.

Murphy says the printed electronics industry is projected to grow to around US$78 billion by 2023, and, as with most emerging technologies, rapid development of a prototype before large firms can play catch-up is vital.

Dr Adnan Younis, who with Professor Sean Li, pioneered development of memory ink at UNSW

“This is a completely different way of potentially providing high-performance memory. There’s no other commercial ready, high-performance memory technology in the market that can be incorporated into a solution and be printed,” he says.

“Our aim is to keep working with the UNSW researchers to optimise the technology, and to partner with a large company that has the technical capacity and market pull to help get the technology into the market quickly.”

Murphy also says the technology isn’t limited to ink-jet printing and can potentially be adapted for a range of other high-tech fabrication processes, such as aerosol jet printing and roll-to-roll processing.

Over the next three months, the company will work with UNSW to optimise the nanocube ink and print memory cells onto silicon, flexible plastic and glass, testing aspects of their performance.

The team is also intending to work with circuit designers to assist in development of a memory device prototype.

Read more about the innovation in The Australian Newspaper.