Astonishing ‘animal patterns’ found on liquid metal surfaces

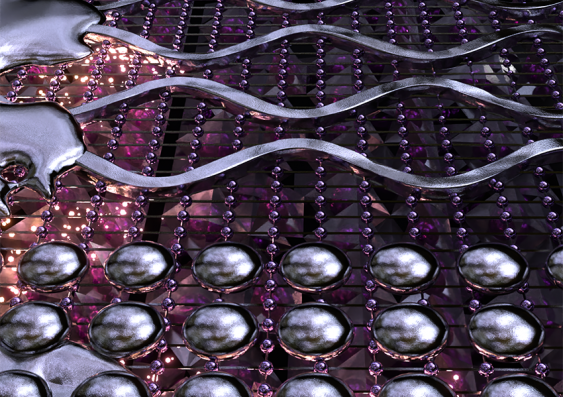

Zebra stripes, leopard spots and other patterns discovered on the skin of frozen metal alloys that defy conventional metallurgy.

Zebra stripes, leopard spots and other patterns discovered on the skin of frozen metal alloys that defy conventional metallurgy.

Neil Martin

n.martin@unsw.edu.au

UNSW Engineering researchers have helped discover diverse types of patterns on the surface of solidified metal alloys – as vivid as the stripes on a zebra or the spots on a leopard.

The findings, published this week in the Nature Nanotechnology journal, defy conventional metallurgy and could lead to exciting advancements in future electronic and optic applications.

Although the study of microscale patterns and compositions of metals and alloys - known as metallography - is well established, research into surface pattern formation phenomenon has long been overlooked.

But researchers from UNSW Sydney and their collaborators from the University of Auckland (the MacDiarmid Institute), RMIT, and UCLA have now changed all that, using observations from two-component metallic mixes, such as gallium-based alloys containing small amounts of bismuth.

These alloys easily melt in the hand and thus make experimental observation and control convenient.

Dr. Jianbo Tang, from the School of Chemical Engineering at UNSW and leading author of the paper, said: “We could observe the surface solidification process under an ordinary optical microscope and I was astonished when I first saw a solidification front on the liquid metal surface creating solid patterns behind it.

“You can imagine the scene of a glacier moving across the ocean surface, but everything seen under our microscope is metallic and microscopic.”

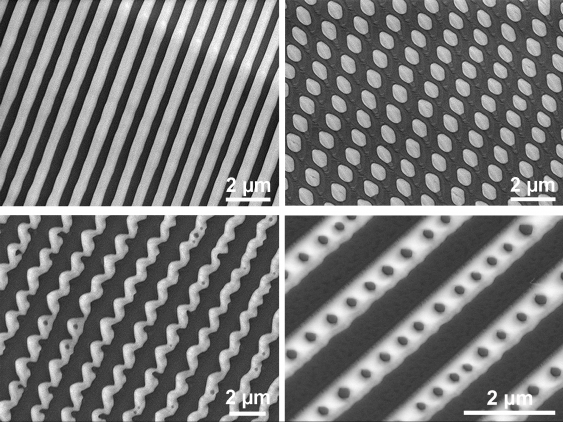

Using an electron microscope, highly ordered patterns including alternating stripes, curved fibres, dot arrays, and some exotic stripe-dot hybrids were observed on the surface of the frozen liquid metal.

To see the finer details of the ‘metallic glacier’, electron microscopy was used, and the researchers observed a kaleidoscope of highly ordered patterns including alternating stripes, curved fibres, dot arrays, and some exotic stripe-dot hybrids.

Surprisingly, the team found that, when these patterns are formed, the abundance of the low-concentration element bismuth at the surface region was much increased. It is this surface enrichment which defies conventional metallurgical understandings.

The researchers also used super computers to simulate the process and found that the small-in-number bismuth atoms, seemingly moving around randomly in a sea of gallium atoms, ultimately accumulated at the alloy surface.

UNSW Engineering’s Professor Kourosh Kalantar-Zadeh, a corresponding author of the study, said: “This previously ignored surface solidification phenomenon improves our fundamental understanding of liquid metal alloys and their phase transition processes.

“In addition, this autonomous surface process can be used as a patterning tool for designing metallic structures and creating devices for advanced applications in future electronics and optics.”

The collaboration between UNSW and the MacDiarmid Institute for Advanced Materials and Nanotechnology was established by Australian Research Council (ARC) Centre of Excellence Future Low-Energy Electronics Technologies (FLEET).