In the belly of the machine

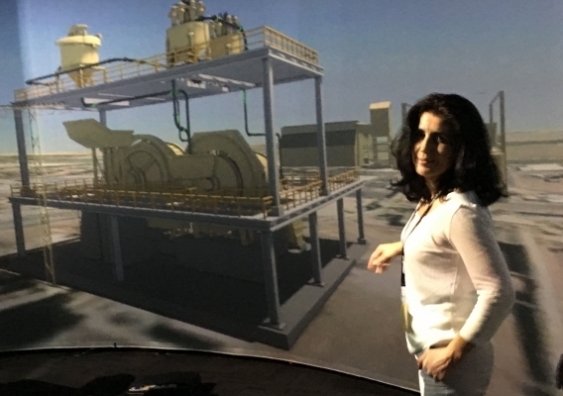

Seher Ata has created a virtual reality module offering her students a fully interactive and immersive journey through the mysterious world of mineral processing.

Seher Ata has created a virtual reality module offering her students a fully interactive and immersive journey through the mysterious world of mineral processing.

Seher Ata has created a virtual reality module offering her students a fully interactive and immersive journey through the mysterious world of mineral processing.

In a world first, it is now possible to take an interactive journey into the fascinating belly of a base-metal concentrator. The project, conceived by Senior Lecturer Seher Ata from Mining Engineering, is the latest in a series of projects using virtual reality (VR) technology for educational purposes at the School.

The module is available in the School’s multimillion-dollar AVIE facility – a 360-degree stereoscopic (3D) immersive interactive visualisation system.

So, what is a base-metal concentrator and what does it do? When base-metal minerals, for example copper, gold and platinum bearing ores, are mined they each have a unique processing route where the metal is separated from the waste material.

“You might have just one tonne of copper within 100 tonnes of rock and the copper mineral might just have a grain size of 100-150 microns, finely disseminated throughout the rock,” Ata says.

“In order to extract the copper mineral, you need to break everything down to that size. That’s what the mineral processing concentrator does through a series of steps. It is these steps that we’ve captured in our virtual reality.”

Ata based the module on a real mineral processing plant at Northparkes Mine in NSW, where her team spent three days accumulating video footage and thousands of images to document every element of the plant.

She then had the information animated to create the immersive 3D experience. It’s interactive, so students can go inside the equipment and actually see how it works. They can see the principles of a process and how they’re connected with neighbouring processing units along the flowsheet.

Although mining and mineral processing are closely related, Ata says in practice there is often a lack of communication between the two, which can have major efficiency implications. It is this disconnect that she wants to address with her module.

“Generally speaking, mining engineers are focused on the extraction of minerals from the ground and process engineers are focused on processing these minerals,” she says.

“To create a really efficient process, however, they must work closely together. As most mining managers are mining engineers, I feel that we have a responsibility to show these future leaders the vital link between mining and processing.

“Northparkes was a good choice because we already have a 3D model of the underground layout of the mine so, now, students can follow the ore from the mine to the processing plant and make a strong connection between the two.”

Undergraduate and postgraduate students have piloted the module and Ata was thrilled when many highlighted it as the best feature of the processing course.

“Because it’s so visual it helps students more deeply understand the connections between the steps. I have definitely seen the benefits in my teaching.”

The module is currently only available in the AVIE facility, but Ata says she plans to have it converted into an app for use in VR headsets.

“This will open the experience up to universities and mining sites all over the world,” she says. “I’m in the process of applying and searching for funding to do this now.”

Ata believes the benefits of using VR in mining education will see its use continue to soar.

“VR is the only real alternative to field trips, which are great in theory but often impractical to organise being both time consuming and expensive,” she says.

“I think we are only just realising how valuable virtual reality technology can be in the future of not only mining engineering but other engineering education, too.”

Read more on the UNSW Engineering website.