UNSW engineers named among the nation’s most innovative

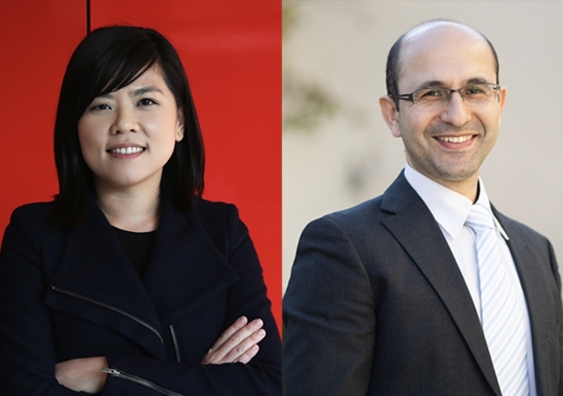

Dr Rona Chandrawati and Dr Farshid Pahlevani have been recognised in the list of Australia’s Most Innovative Engineers for 2020.

Dr Rona Chandrawati and Dr Farshid Pahlevani have been recognised in the list of Australia’s Most Innovative Engineers for 2020.

Louise Templeton

Corporate Communications

+61 (0)413 495 994

louise.templeton@unsw.edu.au

UNSW researchers Dr Rona Chandrawati and Dr Farshid Pahlevani have been named in the list of Australia’s Most Innovative Engineers 2020, an annual program run by Engineers Australia’s create magazine. The awards recognise 30 Australian engineers who are finding creative and innovative solutions to some of the world’s biggest challenges.

Dr Chandrawati, Scientia Senior Lecturer in the School of Chemical Engineering, was named in the young engineers category for her innovative technology that overcomes several challenges when using nitric oxide to treat a range of health conditions.

Nitric oxide is a molecule produced naturally by the human body. It serves a range of biological functions, including wound healing, dilating blood vessels, and lowering eye pressure in glaucomatous eyes. But it’s very difficult to deliver to parts of the body that need it as a medical treatment because it reacts with haemoglobin and effectively disappears into the blood before it reaches the problem area.

To overcome these limitations, Dr Chandrawati developed an enzyme-containing implant technology that produces nitric oxide locally, at the right place in the body, in the right dose, and at the right time. The technology encapsulates enzymes that release nitric oxide into tiny implantable devices. These can be inserted into the body to treat a range of conditions, such as glaucoma, or to coat the surface of cardiovascular stents to help relax blood vessels. Recently, her team discovered that nanomaterials can be engineered and manipulated to act as enzymes to generate nitric oxide.

Dr Chandrawati said: “By manipulating the enzymes and the surface engineering, we can control the exact dose of nitric oxide on demand, as needed. The enzyme coating technology is solution-based, scalable and environmentally friendly.”

Dr Chandrawati enjoyed early success during trials for her technology with ophthalmologists at Duke University and bioengineers at Imperial College London, where it induced vasodilation and reduced eye pressure in mice – proving promising for a treatment to help prevent vision loss in people with glaucoma.

The technology was a hopeful solution to an unmet need in the field of nitric oxide therapeutics and paves the way for engineering the next generation of implants.

Dr Chandrawati said it was an honour to be named in the 2020 Australia’s Most Innovative Engineers among a cohort of amazing engineers.

“I am extremely happy that our work in engineering nanomaterials to solve problems of global significance in health has been recognised,” she said. “It’s all down to great interdisciplinary teamwork. This honour is a valuable recognition of the great work of my team and I am grateful for the support of my research students, postdocs, collaborators and mentors.”

Dr Farshid Pahlevani, a senior research fellow in UNSW’s School of Materials Science and Engineering, was named in the manufacturing and automation category of Australia’s Most Innovative Engineers 2020. Dr Pahlevani has been recognised for his work in developing a world-first, single-step recycling process that transforms steelmaking slag and coffee waste into a sustainable source of agricultural phosphorus.

Phosphorus is an unwanted component of iron ore removed during the steelmaking process. It’s also used in agricultural fertiliser. Australia must import it for domestic food production and agricultural exports due to the country’s phosphorus-poor soils. Most agricultural phosphorus currently comes from rock phosphate mines in Morocco and the mining process pollutes waterways and has created a global dependence on a single non-renewable resource. It’s also made from steelmaking slag, but the traditional process uses acid leaching, which produces waste and is energy-intensive.

Dr Pahlevani developed an innovative process that uses discarded coffee grounds to recover phosphorus in a single step, leaving no hazardous by-products.

“We mix the slag and the coffee grounds, and ensure the ratio, temperature and time are correct to selectively remove only the phosphorus from the phosphorus oxide in the process,” Dr Pahlevani said.

“The phosphorus is removed as a gas, which is passed through argon, then through water, to condense into yellow phosphorus, which can be used as a source of phosphorus.”

Dr Pahlevani believes sustainable sources of agricultural phosphorus are essential to maintaining global food production in the face of rapid population growth, as well as responding to the effects of climate change and depleting natural rock phosphate deposits.

The judges for the 2020 Australia’s Most Innovative Engineers said the innovation is an excellent example of how using innovation can reduce waste and produce a valuable product.

Dr Pahlevani thanked Founding Director of UNSW’s Centre for Sustainable Materials Research & Technology (SMaRT), Professor Veena Sahajwalla, for her tremendous support and guidance throughout the project.