Listening to atoms moving at the nanoscale: study

Understanding how the phenomenon of ‘crackling noise’ occurs at the microscopic scale could have implications for new research in materials science and medicine.

Understanding how the phenomenon of ‘crackling noise’ occurs at the microscopic scale could have implications for new research in materials science and medicine.

Lilly Matson

UNSW Science

0426 656 007

l.matson@unsw.edu.au

Scientists from UNSW Sydney and the University of Cambridge have used novel methods to listen to the sounds of atoms moving under pressure – a phenomenon known as ‘crackling noise’.

These atomic movements occur in avalanches – they are similar to snow avalanches, but made of atoms – and follow very well-defined statistical rules.

Crackling noise can be observed every day, from crumpling paper and candy wrapping, to the crackling of your cereal, as well as in natural occurrences, such as earthquakes.

In a study recently published in Nature Communications, Professor Jan Seidel and his lab, from the School of Material Science and Engineering, were able to record the crackling noise of just a few hundred atoms, in experiments that lasted over eight hours.

The study of crackling noise not only has wide implications across fundamental research fields, but also has a range of practical applications.

“What we might learn from studying crackling noise at the microscopic scale could potentially be applied to the study of crackling noise in a range of different fields, from mining to medicine, to neuroscience and materials science,” says Prof. Seidel. “This means that studying atoms in the lab this way could lead to new information about crackling noise in different contexts.”

Crackling noise is something that was discovered more than 100 years ago by listening to the change of magnetisation in magnets. “It is the movement of atoms in materials under external force that generates noise, like a creaking door, as a macroscopic example,” says Prof. Seidel.

From avalanches to atoms, this same crackling noise occurs at very different scales that can be easily classified by following specific mathematical descriptions and power laws. “These atomic movements occur in avalanches that follow very well-defined statistical rules,” says Prof. Seidel. “So for example, the crackling noise of an earthquake can look very similar to the small atomic movements that we see in our lab.”

To understand the mathematical description of crackling, you need to actually record it. “That's the tricky bit,” says Prof. Seidel. “You need to record about 10,000 or more crackling events, or steps in the process, to reliably extract the mathematical description.”

For years, researchers have tried to minimise the size of the measured areas for crackling noise to the nanometer, but with no luck.

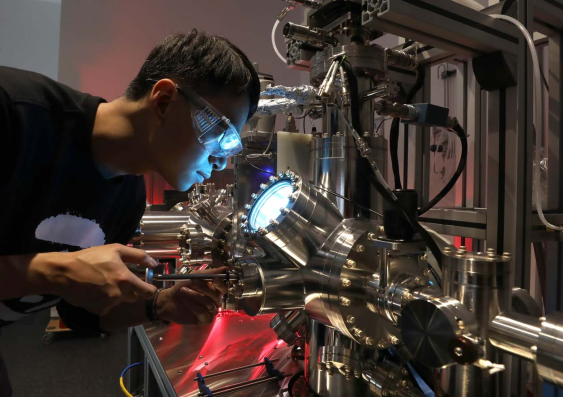

Prof. Seidel, and his team at the ARC Centre if Excellence in Future Low-Energy Electronics Technologies (FLEET), took on the challenge to develop a new method to observe crackling noise at the smallest scale.

The novel method for measuring nanoscale crackling noise involves a minuscule diamond needle and an acoustic enclosure.

“We wanted to record the crackling noise of the selected materials, not the crackling of other external elements. This required a quiet environment, isolated from building vibration, and an extremely hard material for the needle that wouldn’t be impacted by applying a force.

“We tested this on lots of materials and under slightly different conditions,” says Prof. Seidel.

In the end, the best way to record crackling noise at the atomic level was to leave the experiment running over night and for the tip of the needle to slowly press into the material over eight hours.

Together, the team were able to record the crackling noise of approximately 30 nanometre deep areas – the equivalent of the displacement of approximately 100 atoms.

“There we could see, for the first time, the full spectrum of crackling noise and relate it to specific forms of atomic avalanches. This is indeed a breakthrough because we had no idea, just a hope, that for such small indentations we can detect crackling noise! Now we know and the technique can be refined for other specific applications,” says Prof. Seidel.

Importantly, using a scanning probe microscope (SPM), the team were able to scan the material surface topography and locate specific areas that they wanted to target to listen to the crackling.

“Our method allows us to study the crackling noise of individual nanoscale features in materials, such as domain walls in ferroelectrics,” says Prof. Seidel.

Domain walls are very thin regions separating ‘domains’ of materials with opposing properties, such as magnetism. Domain walls play an essential role in the electrical, electromechanical, and optical properties of ferroelectrics – materials that have a spontaneous electric polarisation. “These are particular areas of interest as the types of atom avalanches differ around these structures when the material deforms.”

This research raises new questions from a fundamental research point of view, Prof. Seidel explains. “We can now look at different types of nanoscale features in materials and study how they crack or how they deform and that might enable the development of completely new technology.

“This is the exciting bit about doing research, for me. Sometimes if you do something completely different, it might lead to a new field or information that you otherwise couldn't find, just because you're not looking for it.”

One of the method’s most intriguing aspects is the fact that individual nanoscale features can be identified and located by imaging the material surface before indenting it and making it crackle. “For example, we might learn more about the behaviour of domain walls, that are particularly interesting for making energy-efficient electronics and better solar cells.”

But as well as fundamental questions, this latest study has real-world applications. This new technique has the potential to advance diverse fields, such as medical research, material degradation and corrosion studies.

“Now that we know that crackling noise can be measured at very small length scales, potential new applications are significant,” says Prof. Seidel. “We can look at metals and focus on weak spots where the metal breaks and concentrate on the breaking process on an atomic scale. Medical and in-vivo investigations of biological samples are also becoming feasible with some modifications to the new technique.”