Mimics human tissue, fights bacteria: new biomaterial hits the sweet spot

A new lab-made substance mimics human tissue and could reduce or replace the use of animal-derived materials in biomedical research.

A new lab-made substance mimics human tissue and could reduce or replace the use of animal-derived materials in biomedical research.

Lachlan Gilbert

UNSW News & Content

(02) 9065 5241

lachlan.gilbert@unsw.edu.au

Scientists at UNSW Sydney have created a new material that could change the way human tissue can be grown in the lab and used in medical procedures.

The new material belongs to a family of substances called hydrogels, the essence of life’s ‘squishy’ substances found in all living things, such as cartilage in animals and in plants like seaweed. The properties of hydrogels make them very useful in biomedical research because they can mimic human tissue, allowing cells to grow in a laboratory.

There are also human-made hydrogels that are used in a broad range of commodity products ranging from food and cosmetics to contact lenses and absorbent materials, and more recently in medical research to seal wounds and replace damaged tissue. While they might function adequately as space fillers that encourage tissue growth, synthetic hydrogels fall short in recreating the complex properties of real human tissue.

Read more: Scientists use materials to make stem cells behave like human embryos

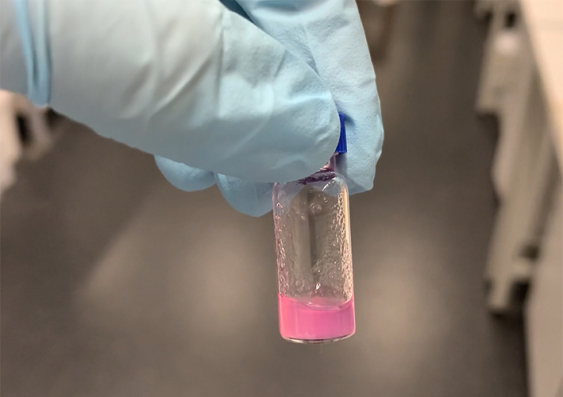

But in a research paper published today in Nature Communications, scientists from UNSW describe how a new lab-made hydrogel behaves like natural tissue, with a number of surprising qualities that have implications for medical, food and manufacturing technology.

Associate Professor Kris Kilian from UNSW’s School of Materials Science & Engineering and School of Chemistry says the hydrogel material is made from very simple, short peptides, which are the building blocks of proteins.

“The material is bioactive, which means that encapsulated cells behave as if they are living in natural tissue,” A/Prof. Kilian says.

“At the same time, the material is antimicrobial, meaning that it will prevent bacterial infections. This combination lands it in the sweet spot for materials that might be useful in medicine. The material is also self-healing, which means that it will reform after being squished, fractured, or after being expelled from a syringe. This makes it ideal for 3D bioprinting, or as an injectable material for medicine.”

Ashley Nguyen, a PhD student in the UNSW School of Chemistry and first author on the paper, made this discovery during the Covid19 lockdown using computer simulations. Ms Nguyen was looking for molecules that self-assemble – where they spontaneously arrange themselves without human intervention – and stumbled upon the concept of ‘tryptophan zippers’. These are short chains of amino acids with multiple tryptophans that act as a zipper to promote self-assembly, which have been dubbed “Trpzip”.

“I was excited to identify a unique peptide sequence using computational simulations that might form a hydrogel,” says Ms Nguyen.

“After we returned to the lab, I synthesised the top candidate and was thrilled to see it actually form a gel.”

Ms Nguyen says the discovery of this hydrogel has the potential to be an ethical alternative to the widely used natural materials.

“Natural hydrogels are used all over in society—from food processing to cosmetics—but require harvest from animals which poses ethical concerns,” she says.

“Also, animal-derived materials are problematic for use in humans because of the negative immune response that occurs. With Trpzip, we have a synthetic material that not only shows potential in many areas where natural materials are currently used, but also could outperform them in others, such as clinical research.”

Read more: Scientists use novel ink to 3D-print 'bone' with living cells

To test the viability of Trpzip in biomedical research, A/Prof. Kilian’s team partnered with researcher Dr. Shafagh Waters in the School of Biomedical Sciences at UNSW Sydney, who uses Matrigel – a hydrogel harvested from mouse tumours – for the culture of patient tissue in her research.

“Matrigel has some disadvantages in research use because every batch is different. A chemically defined alternative could be cheaper and more uniform, which would prove highly beneficial to biomedical research,” says Dr Waters.

A/Prof. Kilian notes that the natural materials business is a billion-dollar industry and says the team is keen to explore pathways to commercialisation.

“We think that Trpzip hydrogels and materials like it will provide a more uniform and cost-effective alternative to animal-derived products. It would be a tremendous outcome if our material reduced the number of animals used in scientific research.”

The next phase of research will involve partnering with industry and clinical scientists to test the utility of Trpzip gels in tissue culture and explore applications that highlight the unique dynamic characteristics like 3D bioprinting and stem cell delivery.